Services:

Specialty NDE ServicesWIP - Window Inspection Probes

Full Length Immersion Scanning System

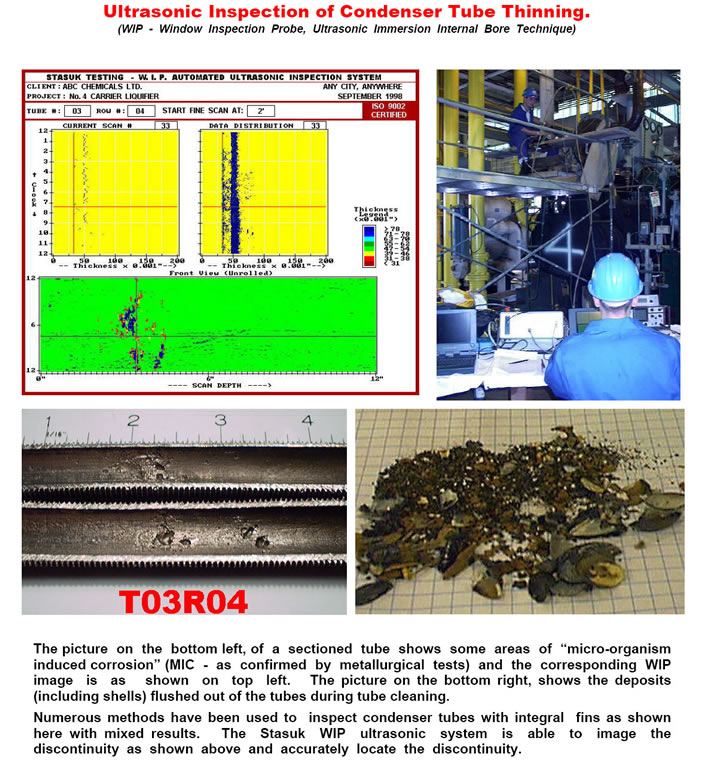

The WIP series probes are highly versatile with various centering and sealing systems our probes can provide critical thickness data from tubes in any orientation and diameters from 1/2" to 3" ID. The WIP series probes can provide linear resolution to any increment set in the system and using its built in seals it can carry a water column as it travels to provide highly accurate thickness data. Unlike IRIS type systems, the WIP does not require tube plugging and can travel past most bends while maintaining higher data collection rates. WIP also has major advantages over eddy current systems, providing true thickness and positional data as well as the ability to scan both ferous and non-ferous tubing. Baffles, tubesheets and fins do not present false indications that occur with eddy current methods.

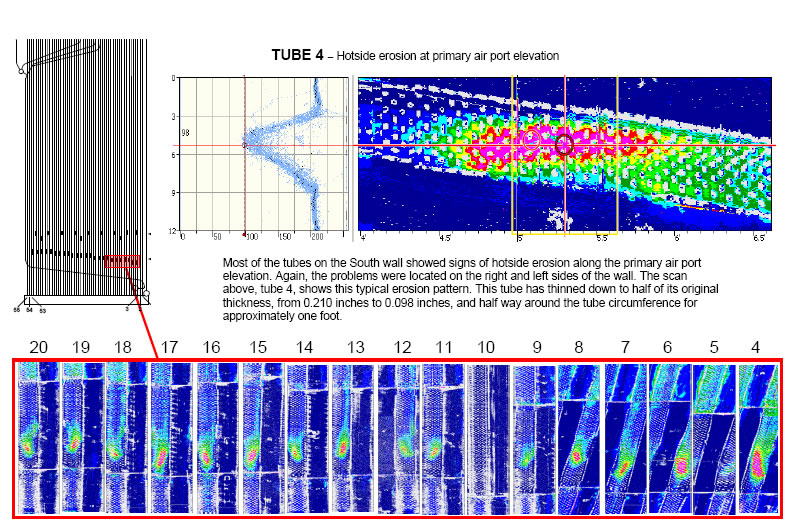

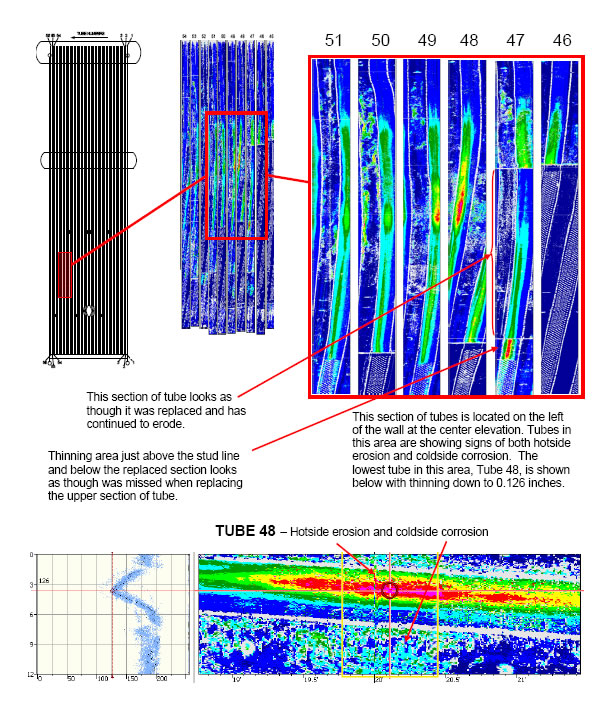

Above is a typical report showing imaging of full Length Wall scanning of a B&W Recovery Boiler with Lower Studded Walls. Note the scanning resolution can determine patterns within the studded areas surrounding the primary airports.

Above is a typical report showing imaging of full Length Wall scanning of a B&W Recovery Boiler with Lower Studded Walls. Note the scanning resolution can determine patterns within the studded areas surrounding the primary airports.

On boilers, full wall tubes can be imaged including hidden corrosion zones behind refractory or buckstays. Access is gained through the drum roof tubes, rear wall tubes, hand hole caps on headers or by access windows cut into the tube. Our probes can be inserted and both cold and hot sides of the tubes can be imaged for lengths up to 60'. See Below for full wall scan samples.

On exchangers, concentrators or evaporators our WIP probes can be run from the top down or bottom up as well as on horozontal tube runs.